1. F A Q FOR ADITRON INDIA PVT LTD ROTARY JOINTS FOR BETTER AND LONGER LIFE —– INSTALAION PROCESS

.Precautions on Transport and Storage

3.Precautions on Installation and Pipe Laying

Product adjustment is not required before installation.

ADITRON INDIA PVT LTD ROTARY JOINTS FOR BETTER AND LONGER LIFE

(1)Be sure to read this PAGE before use.SAVE THIS WEB SITE so

that it can be referred to at any time. (2)Transport,storage,installation,piping,operation,or maintenance of this

product should be carried out by an experienced expert.

(3)In order to prevent product malfunction resulting in bodily accidents or

damage to peripheral equipment,be sure to follow the warnings,

cautions,and instructions described .

(4)Never disassemble or modify this product because doing so is dangerous.

(5)Instruction for respective series are available on our website.See

them while reading this l.

If the instruction contact our TECH

TEAM for assistance.

In order to prevent injury to workers,product damage,or fluid leakage,

follow the following instructions.

(1)To transport a product that weighs over 25kg,use appropriate lifting

equipment.

(2)Do not drop or subject the product to undue impact while it is being

transported.

(3)Wrap the product before storing it to prevent the entry of foreign objects.

(4)Store this product in a dry environment at 10℃ to 40℃.

(5)The storage period should be within a maximum of two years.

In order to prevent injury to workers,product damage,or fluid leakage,

follow the following instructions.

(1)Take the product weight into consideration before installing the product.

Use equipment such as a crane as necessary.This work should be

performed by two or more persons.

FOR

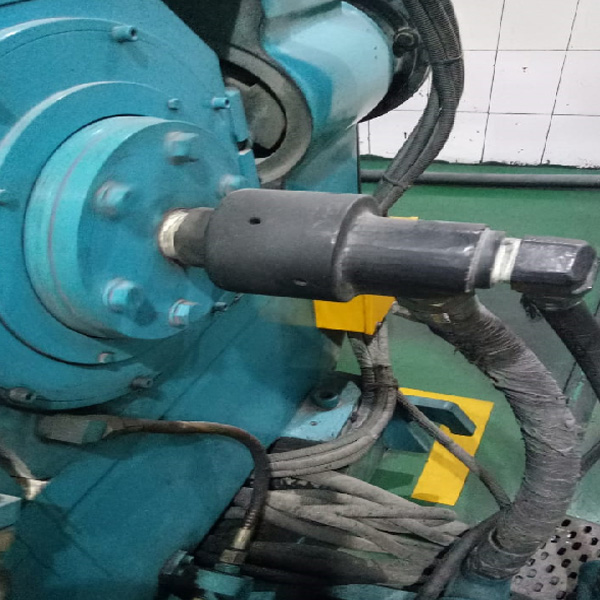

INSTALATION BETTER AND OPTIMUM PONGER LIFE bend the tube

in the rotation direction. Flexible Metal Tube

Rotation Direction of round bar that comes in contact with the

rotation stopper must be smooth.)

In order to prevent bodily accidents or damage to peripheral equipment,

1.If your product has an inspection hole,be sure to install it so that the

hole faces downward.Also,do not block the hole.

2.Use a hose for product connection suitable for characteristics of fluid

used and operating conditions(pressure,temperature). (8)Do not secure the rotation stopper to an anti-rotation plate or a round bar.

An

example of a measure using a round bar is shown below.(Only for

products with rotation stoppers)

(2)Remove any foreign objects in such flow passages as a pipe or a roll

before product installation.If the fluid contains foreign objects,install a

strainer at the flow passages.

(3)When inserting an internal pipe into the rotor,do not allow the pipe to hit

inner parts.

(4)Install so that no center misalignment or inclination occurs between the

rotation axes of the rotor and a roll.

(5)Use a flexible metal tube or a rubber hose with adequate flexibility to

connect to the product.Steel pipes should not be used for pipe laying.

(6)Avoid such pipe laying where heavy items such as valves are suspended

from the product.

(7)When installing a flexible metal tube,slightly bend it in the rotation

direction of roll.Furthermore,carry out pipe laying work so that excessive

“tension”,“compression”,“torsion”,or“bending”is not caused.(See

the figure below.) WARNING

If a malfunction occurs during the warranty period,contact us or the distributor and send

the product to us.Be sure to carefully pack the product for protection before sending it.

After receiving the product,we will confirm the malfunction.If the malfunction was clearly caused by the materials of product components or the manufacturing method,we will repair the product in question or replace it with a new one free of charge. Product Warranty Greasing (1)Periodic greasing is required for grease-type products with grease nipples.Be sure to remove the grease outlet plug before greasing. Then fill the grease through the grease nipple.Continue to fill until grease comes out from the grease outlet. (2)greasing frequency 30–80–90 DAYS DEPENDING UPON ITS USE AND WORKING CONDITIONS . (3)Use the same brand of grease as the one filled in the product before shipment from our company. e 6.Product Warranty (1)Perform operation within the service conditions.Moreover,do not operate under conditions where both pressure and rotation speed are close to the max.values. Doing so significantly reduces product lifetime. (2)When starting operation,check for abnormal rotation(center runout, abnormal noise,etc.)or fluid leakage from the product while gradually increasing fluid pressure and roll rotational velocity. (3)During rotation or high-temperature/pressure fluid flow,keep well away from the product to prevent injuries or burns.Do not directly touch rotating or hot parts during operation. (4)If operation is continued under a center runout condition,product damage or fluid leakage may result. (5)The occurrence of surging or water hammer can cause product damage or fluid leakage.Avoid such occurrence. (6)Do not perform dry operation(operation without fluid flow)for a long time. The product lifetime becomes shortened. (7)If the product is left as is for a long time during operation shutdown,rust may occur,causing fluid leakage after operation restart.Clean flow passages for the product,pipes,and roll before restarting operation

.

●Daily inspection

Visually check pipe connections,product connections,and the product for

fluid leakage.If fluid leakage is detected,stop operation and immediately

repair the product or replace it with a new one.

5.Inspection and Maintenance 1.Warranty period <New products>

One(1)year and six(6)months after shipment(from the manufacturing

date)or one(1)year after installation,whichever comes first.

<Repaired products> Six(6)months after shipment(from the manufacturing

date). 2.We charge a fee for repairs in any of the following cases.

①Failure after the warranty period has expired

②Failure caused by use of the product deviating from the service conditions

③Failure caused by misuse(improper storage,installation,pipe

laying,operation or maintenance,etc.)

④Failure caused by fluid contaminants or foreign objects in the fluid

⑤Failure caused by relocation,transport,or falling of the product after delivery

⑥Failure caused by disassembly,repair,or modification done by personnel other than our

service personnel

⑦Failure of the product attributed to using materials or according to standards specified by

the customer

⑧Failure of the product attributed to using materials provided by the customer

⑨Failure caused due to unavoidable acts of nature such as fires or other natural disasters

3.Scope of responsibility

Our responsibility shall be limited to repairs,replacements,or transport expenses covered by

this product warranty provision.Expenses or damages caused by said failures above shall

not be covered. 4.Applicable regions This product warranty provision

shall be applicable to products installed in INDIA ONLY LIMITED TO

INDIA ONLY . 5.Another agreement

If another product warranty agreement is made separately with us and clearly states that said

agreement shall have priority over this product warranty provision,this provision shall not be

applicable.

6.This product warranty provision shall not restrict the customer’s legal rights.

1.If operation is continued with fluid leakage not being repaired,

bodily accidents or damage to peripheral equipment may result.

2.In order to prevent bodily accidents due to residual fluid in the

product or pipes,remove the product after fluid has been

completely drained from the product or pipes and temperature

has dropped to room temperature.

WE HAVE 5300 MODELS TO CHOOSE FROM AND 23000 CUSTOMERS IN INDIA IN LAST 35 YEARS OF MANUFACTURING–

DR N GOEL ARUN GOEL DIRECTORS AND FOUNDERS 9810133942–9312778387