ROTATING JETS DM-005

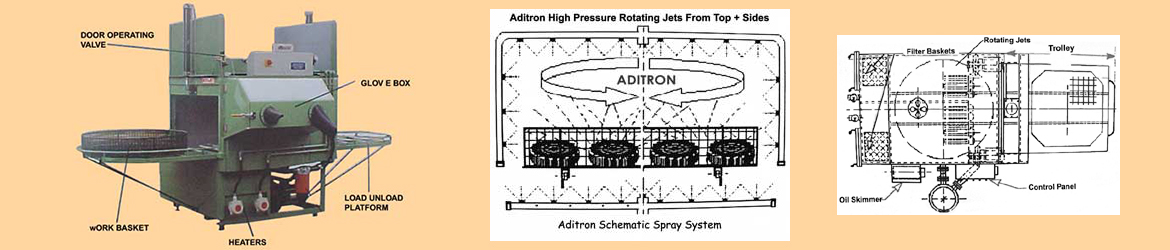

The Aditron DM-005 washers are designed for the spray cleaning of medium and large sized heavy parts and for heavy duty or high productivity jobs.

The Aditron DM-005 washers avoid all the drawbacks which arise from the use of a rotating platform for heavy parts and in addition give faster and more efficient cleaning plus a fully usable and accessible platform – basket.

The operating principle is based on rotary jets rotating through a specially designed manifold with four spray bars with special pattern nozzles. The revolving movement ensures a perfect cleaning of the parts.

Aditron Degreasing Cleaning & Washing Machines System are made to order

ROTATING JETS DM-008

The cabin is made from sheet metal reinforced and welded on a rigid tubular frame. The front side, the door and the covers are stainless steel. The tank is insulated and protected with rust free panels.

The pump is located on the one side while the filtering system is on the opposite side both easily accessible from outside for maintenance. The filtering system is fed by gravity and consists of four elements for gross soil and one of large dimensions to retain fine solid contaminants.

The Rotating Jet washers are manufactured in five different size models or with air operated vertical door and load platform.

Aditron Degreasing Cleaning & Washing Machines System are made to order

CONVEYORISED Degreasing DM – 019

The ADITRON 2 to 6 stage spray washing cleaning and degreasing systems – washers are designed for continuous operation jobs and can be single or multi stage. That makes the tunnel system suitable for many applications even if a diversified spray process is required for difficult-to-clean parts or for mass-production.

The tunnel system is based on the pass-through principle and is not influenced by the length of materials to be treated. If desired a dipp stage with Ultrasonics can be added for soaking application.

Aditron Degreasing Cleaning & Washing Machines System are made to order

DM-53 : Conveyor System

DM-54 : Dipping + Dunking + Agitation

DM-55 : Panel of Conveyorized Machine

DM-56 : Control Panel of Dipping Machine

DM-57 : Two Dipp Systems inline

DM-58 : Multi Stage Transporter

DM-59 : Three Stage Conveyor

DM-62 : Inside View of Conveyorized

DM-65 : Rotating Jets High Pressure

DM-66 : Curtain of Conveyor System

DM-67 : Dipping with Loading Stage

DM-68 : Single Stage Rotary Jets

DM-69 : Two Stage Vapo Dipp

DM-70 : Vapour Degreaser with Basket

DM-73 : Conveyor for one Piece

DM-075 : Multi Stage Transporter Type Dipping

DM-76 : Stainless Steel Conveyorised

DM-077 : Multi Stage Phosphating Transporter

DM-029 : Small Conveyor

Robust – Heavy Duty Body / Structure

The ADITRON rotary jets high jet pressure spray washing machine is designed to wash / degrease and rinse components in a single cabinet. Robustly fabricated from 6 mm mild steel plate, the machine comprises a front loading wash cabinet located over heated media sumps with manual or a pneumatically actuated optional – vertical sliding door to the front. Electric heating is standard.

Energy Efficient

As far as possible the complete resoirvoir of the machine is insulated with 50 mm mineral / glass wool slabs held in position and protected by an outer skin of 20s gauge, galvanized sheet metal, finish painted with metal primer and 2 coats of final painting – to customer specifications.

Enhanced Performance of ADITRON Rotating Jets Machine

Cleaning / Degreasing / Washing is achieved by direct & indirect impingement of high pressure media, hot (70-80° C) your selected detergent solution, delivered at a nominal 4 – 5 bar pressure by means of spray arms rotating around a mesh basket containing the compnents – the parts to be cleaned. The imported stainless steel nozzles with Vee pattern jetting is fitted to the spray arms, set in line such that the sprays merge to provide all round coverage as the spray arms rotate – as explained in the photograph Schematic Spray Pattern of the Aditron Rotating Jet Machine.

The upper spray rotating arm that jets from above and all sides, has a slow rotary motion, achieved by means of a leakless coupling and a gear drive. The slow rotation motion aids jet penetration, eliminates shading and generally improves cleaning efficiency. The jet driven lower spray arm is located beneath the load bearing rails and jets upwards to clean the underside of components.

Carrying the Components in Heavy Duty Baskets with Wheels

Load bearing rails within the ADITRON machine are aligned with similar rails located on an external fixed platform or mobile trolley for basket bogie transfer, alternatively, roller track may be fitted in the rails. Nominal load weight for manual transfer is recommended. This can be increased dramatically. (Optionally, power load transfer is available at extra cost).

This design overcomes all problems faced by the customers in the rotating Basket plants of rotating loaded heavy basket – stopping at location and loading unloading problems – this design is faster – more effective – efficient.

Filtration

Return flow filter baskets are fitted as standard with the option to fit in line particulate filtration between the pump and the jets with filteration system attachment elements available from 800 microns to 10 microns.

Oil Skimming

A Motorised skimmer or Special type oil skimmer is offered to the wash sump to periodically remove surface oil contamination from the cleaning solution.

Steam / Fume Extraction at extra cost – if required

Steam extraction by means of a bifurcated fan is fitted as optional or a condenser unit may be fitted.

EFFICIENCY

Efficient cleaning is achieved by direct and indirect impingement by high volume hot detergent, delivered under high pressure from rotating spray bars. These contain VEE pattern jets which merge the spray to ensure 100% coverage of the washing space. High heat input gives rapid heat up time and fast temperature recovery. Components rapidly FLASH dry on removal from the ADITRON machine.

LOW RUNNING COSTS

Efficient insulation of the reservoier and total covered unit outer surfaces keeps heat inside cabinet, with heat loss during load/unload operations being prevented by a shed plate covering the integral sump. The machine uses a recirculating hot water system containing as little detergent keeping chemical costs low.

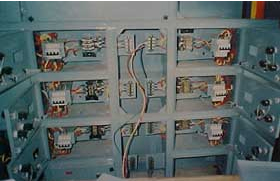

CONTROLS AND ANCILLARY EQUIPMENT

ADITRON Degreasing / Washing / Cleaning Machines are supplied complete with a fully wired control panel containing safety features with relays, contractors and cycle timers. The panel door houses an interlocking isolator, cycle start and emergency stop button, on/off heater switch and indicator lights. On most machines standard fittings include temperature control, temperature and pressure indicator gauges, a 1½ sump drain valve, a large clean-out door and a removable perforated return flow filter.

ADITRON OFFERS STANDARD AND CUSTOMISED END TO END SOLUTION FROM DEGREASING- CLEANING – DRYING – RUST PREVENTIVE COATING CAN BE CUSTOMISED END TO END SOLUTIONS BASED ON YOUR INPUTS AND SPECIFIC REQUIREMENTS APPLICATION THAT IS MOST SUITABLE FOR YOUR INDUSTRIAL PARTS- INDUSTRIAL COMPONENTS-.AUTO COMPNENTS MAY MRO- DEFENCE- AERO SPACE-RADARS = OR YOU NAME IT WE HAVE IT

ADITRON INDIA PVT LTD NOIDA OFFERS ALMOST NILL MAINTENANCE OR SELF MAINTAINABLE DEGREASING SYSTEMS AS ALL COMPONENTS PARTS USED ARE BEST INDIAN MAKE SELECTED BY CUSTOMER THE USER TO GIVE CONSISTENT PRODUCTIVITY AND CONSISTENT QUALITY IN ACHIEVING YOUR DEGREASING AND CLEANING VALUES WITHOUT HUMAN ERROR

AT ADITRON INDIA PVT LTD NOIDA WE ENSURE OPTIMUM CHEMICALS ARE SUGGESTED TO TAKE CARE OF ENVIRONMENT NO POLLUTION ISSUE WHEATHER IT IS A VAPOUR DEGREASER IN SS OR ROTARY JET HIGH PRESSURE DEGREASER CLEANER OR CONVEYOR TYPE FOR PLASTIC CARATS SHOES CHAPPALS CAPS GLOVES DEGREASING CLEANING FROM MUCK GREASE OR ANY OTHER CONTAMINATIONS FROM CASTINGS FORGINGS MACHINED PARTS STAMPINGS MOULDINGS EXTRUDED PARTS

WE ARE SURE OUR DESIGN TEAM WILL SOLVE YOUR SIMPLE OR CRITICAL DEGREASING CLEANING ISSUES AT OPTIMUM COST TO JUSTIFY THE INVESTMENT RESULTING IN IMPROVED QUALITY OF YOUR END FINAL PRODUCTS FOR FURTHER DETAILS CONTACT OUR DESIGN DEPTT DR N GOEL OR ARUN GOEL 9810233942 / 9312778387 ADITRONNOIDA57@GMAIL.COM OR AROON2357@GMAIL.COM CHAT/ EMAIL / WHATSAPP OR DIRECTLY CHAT WITH FOUNDERS AND DIRECTORS DR N GOEL OR ARUN GOEL AT ADITRON INDIA PVT LTD NOIDA NEW DELHI